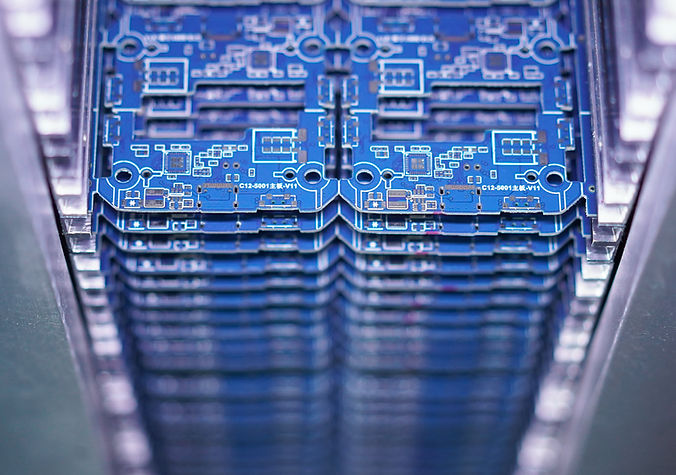

Printed Circuit Board Assembly (PCBA) Services

At JosephSan Private Limited, we specialize in high-quality Full Turn-key Printed Circuit Board Assembly (PCBA) services, catering to industries that demand precision, reliability, and efficiency.

Our PCBA solutions are designed to support engineering samples and mass production with a strong focus on quality assurance and cost‐effectiveness.

Why Choose JosephSan for PCBA?

1. State-of-the-Art Assembly Techniques

JosephSan utilizes advanced assembly technologies to deliver high-precision, high-reliability PCBA solutions for various industries. Our cutting-edge processes ensure every assembly meets the highest industry performance, durability, and quality standards.

Advanced Assembly Capabilities

a. Surface Mount Technology (SMT) – High-speed, automated pick-and-place machines ensure precise component placement, supporting fine-pitch, high-density interconnects (HDI), and miniaturized components.

b. Through-Hole Technology (THT) – Ideal for components requiring high mechanical strength, such as connectors, transformers, and power modules.

c. Mixed-Technology Assembly – Combines SMT and THT to support hybrid PCB designs, ensuring compatibility with varied component types.

d. Ball Grid Array (BGA) Assembly – We provide BGA assemblies with X-ray inspection to ensure secure solder joints and electrical integrity for advanced PCB layouts.

e. High-Layer-Count PCBs – We fabricate and support multi-layer PCBs with complex interconnections, making them suitable for high-performance applications.

Precision Manufacturing & Quality Assurance

f. Advanced Pick-and-Place Machines – Ensure high-speed, highly accurate component placement, reducing errors and enhancing efficiency.

g. Reflow & Wave Soldering – Optimized reflow soldering for SMT components and wave soldering for THT ensure strong, reliable solder joints.

h. Selective Soldering – This method is used for through-hole components, preventing heat damage to adjacent SMT parts while ensuring consistent soldering quality.

i. Custom Assembly Solutions – We offer conformal coating, potting, PCB depanelization, and specialized assembly techniques only as add-on services to enhance durability and reliability. These customized services are not offered as standalone solutions.

Our state-of-the-art assembly techniques enable us to manufacture high-quality PCBAs for industrial electronics, consumer electronics, automotive, and more. Whether for small-scale engineering sampling or full-scale production, we ensure precision, reliability, and efficiency in every board we produce.

2. End-to-End Support

At JosephSan, we provide comprehensive, end-to-end support for every stage of the PCB assembly process, ensuring a seamless transition from concept to completion. Our expertise begins with an in-depth review of design files, where we assess manufacturability and suggest optimizations to enhance efficiency and cost-effectiveness.

With access to a trusted global supply chain, we source high-quality components, mitigating risks such as counterfeit parts and procurement delays. Our capabilities extend beyond assembly to include advanced inspection and testing solutions, guaranteeing reliability and performance.

For customers requiring full product integration, we offer final assembly, custom packaging, and logistics support, ensuring that each PCB reaches its destination and is ready for deployment. Whether it’s prototyping, mass production, or turn-key manufacturing, JosephSan delivers a streamlined and hassle-free experience, allowing clients to focus on innovation while we handle the complexities of production.

3. Industry-Standard Quality Control

Quality is embedded at every stage of our Printed Circuit Board Assembly (PCBA) process. We adhere to globally recognized quality standards to ensure that every PCB meets performance, safety, and durability expectations before it reaches the customer.

Multi-Stage Quality Control Process

a. Incoming Material Inspection (IQC) – All electronic components and raw materials undergo rigorous visual inspection to verify authenticity, compliance, and specifications before assembly.

b. In-Process Quality Checks (IPQC) – Our conveyor belt production lines integrate real-time monitoring at critical assembly stages to detect and correct issues before they escalate.

c. Automated Optical Inspection (AOI) – High-resolution AOI systems scan PCBAs immediately after surface-mount technology (SMT) assembly for solder joint quality, misalignment, missing components, or defects.

d. X-ray Inspection for BGA and Hidden Solder Joints – Advanced X-ray analysis is used for Ball Grid Array (BGA) components and hidden solder joints, ensuring strong and reliable connections.

e. Functional Testing at Key Production Stages – PCBs are tested at multiple stages along the assembly line to ensure they function correctly before final integration into the complete product.

f. Final Product Inspection (FQC) – At the end of the conveyor belt, fully assembled electronic products typically undergo a comprehensive final test to verify functionality and reliability before packaging.

However, some customer-specific PCBAs may not undergo this test due to factors such as:

i. Incomplete assembly (e.g., missing mechanical enclosures or not provided).

ii. No firmware is uploaded at this stage.

iii. No need for functional testing as per customer instructions.

iv. A functional tester was absent from the customer.

v. Prototype-only builds, where testing is not required.

vi. The PCBA is not integrated into a final product, making full testing impractical.

JosephSan can integrate tailored quality control solutions upon request for customers requiring customized functional testing.

g. Packaging Quality Assurance – All products are securely packed in protective boxes, cartons, and pallets before shipment, preventing damage during transportation.

We don’t just build PCBAs – we embrace quality from start to finish, ensuring that every product leaving our factory meets the highest industry benchmarks.

4. Flexible Production Capabilities

Every customer has unique production requirements, ranging from low-volume engineering sampling runs to high-volume mass production. Our flexible PCBA solutions ensure that businesses of all sizes can achieve their manufacturing goals without compromising quality, cost, or lead time.

Engineering Sampling to Production – Scalable Solutions

a. Low-Volume, High-Mix Engineering Sampling – Whether you need a single engineering sample or a small batch for R&D, we offer quick-turn PCBA services with fast iterations to accelerate your product development cycle.

b. Mid-Volume Production – This option is ideal for pilot runs and pre-production batches, helping customers refine their products before committing to full-scale production.

c. High-Volume Manufacturing – Our state-of-the-art facilities and automated production lines enable efficient mass production with consistent quality and cost optimization.

Custom PCBA Solutions

d. Tailored to Customer Requirements – Every project is different. We can customize assembly solutions based on unique component sourcing, PCB layouts, assembly techniques, and specialized materials.

e. Design-for-Manufacturing (DFM) Support – Our team works closely with customers to optimize PCB designs for efficiency, manufacturability, and scalability from the early stages.

f. Mixed Technology Assembly – We handle Surface-Mount Technology (SMT), Through-Hole (THT), and Hybrid PCBA processes, allowing for diverse and complex designs.

With JosephSan's Flexible Production Capabilities, customers benefit from a scalable, efficient, and high-quality PCBA service, no matter the size or complexity of their project.

5. Global Supply Chain

Situated in Singapore, a global hub for electronics manufacturing and supply chain logistics, JosephSan leverages its strategic location to provide seamless, cost-effective, and reliable PCBA solutions for customers worldwide. Our extensive global network ensures efficient sourcing, streamlined logistics, and on-time delivery – no matter where you are.

Strategic Global Trade Links

a. Access to Leading Component Suppliers – We work with trusted global distributors and manufacturers to source high-quality electronic components, ensuring authenticity, traceability, and compliance with international standards.

b. Cost-Optimized Procurement – Leveraging our global network, we negotiate competitive pricing and optimize sourcing strategies to keep costs in check without sacrificing quality.

c. Efficient International Logistics – Our well-established supply chain network enables fast and reliable shipping for small prototype batches or high-volume mass production.

Seamless Supply Chain Management

d. Multi-Supplier Sourcing Strategy – We mitigate risks by sourcing from multiple suppliers and alternative markets, ensuring business continuity even during supply chain disruptions.

e. Global Compliance & Trade Regulations – Our expertise in international trade laws and regulatory compliance (RoHS, REACH, IPC Standards) ensures smooth customs clearance and adherence to global quality standards.

f. Just-in-Time (JIT) Inventory Management – To optimize production schedules and reduce excess inventory costs, we implement JIT strategies, enabling faster time-to-market for our customers.

With our Global Supply Chain, customers benefit from a well-connected, agile, and resilient sourcing and logistics ecosystem that ensures timely, high-quality, cost-effective PCBA solutions.

6. Dedicated Production Engineering Support

Our expertise lies in efficient and high-quality PCBA manufacturing. While customers design their own PCBs, our Production Engineering team ensures that every assembly process is optimized for smooth, scalable, and defect-free production. We provide practical recommendations that improve manufacturability, streamline assembly, and enhance yield rates – without altering the fundamental PCB design.

Enhancing Manufacturability & Production Efficiency

a. Design for Manufacturability (DFM) Guidance—While we do not alter PCB designs, our engineers analyze Gerber files, component footprints, and panelization layouts to identify potential assembly challenges and recommend customer-approved adjustments for smoother production.

b. Design for Assembly (DFA) Optimization – We assess component placement, solderability, and PCB layout spacing to prevent issues like solder bridging, tombstoning, and misalignment and ensure consistent quality during mass production.

c. Production Process Optimization – Our Surface Mount Technology (SMT) and Through-Hole Technology (THT) assembly lines are continuously fine-tuned to maximize efficiency, reduce cycle times, and minimize production errors.

Collaborative Production Support

d. Panelization & Stencil Design Advice – We work with customers to optimize panel designs and solder paste stencil openings, ensuring better yield rates and soldering precision.

e. Material & Component Handling Expertise – Our team implements ESD-safe handling, moisture-sensitive device (MSD) protocols, and tape-and-reel management to maintain component integrity throughout production.

f. Real-Time Manufacturing Troubleshooting – Should unexpected process inefficiencies arise, our engineers provide rapid problem-solving to keep production on schedule.

Our Production Engineering expertise ensures that your PCBA moves seamlessly from design to mass production, with optimized efficiency, reduced defects, and reliable scalability.

7. Compliance with Industry Certifications

We uphold the highest standards of quality, safety, and environmental responsibility in every PCBA we manufacture. Our strict adherence to globally recognized industry certifications ensures that customers receive reliable, compliant, and high-performance assemblies for even the most demanding applications.

Certified Quality & Compliance Standards

a. IPC-A-610 (Class 2 & Class 3 Standards) – Ensures precision soldering, component placement accuracy, and defect-free assemblies, meeting stringent acceptance criteria for both general and high-reliability electronics.

b. ISO 9001: Quality Management System – Guarantees consistent production quality, streamlined processes, and continuous improvements to meet customer expectations.

c. RoHS (Restriction of Hazardous Substances) – Ensures that our PCBAs are manufactured without hazardous materials such as lead, mercury, and cadmium, making them environmentally friendly and compliant with global safety regulations.

d. REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) – Certifies that our products meet European Union (EU) regulations on the safe use of chemicals, ensuring compliance with international environmental laws.

Application-Specific Compliance

e. Automotive-Grade Manufacturing – Our PCBA processes comply with automotive standards, ensuring high reliability, thermal stability, and long-term durability for vehicle electronics.

f. Medical & Industrial Compliance – We meet the stringent manufacturing requirements for medical devices, industrial control systems, and mission-critical electronics, ensuring safety, reliability, and regulatory approval.

g. Aerospace & High-Reliability Applications – Our PCBAs meet the highest workmanship and component integrity standards for industries demanding exceptional quality and durability.

Compliance isn’t just about meeting regulations – it’s about delivering quality, reliability, and safety in every PCBA we produce. Our customers can trust that every assembly is built to perform, built to last, and built to global standards.

8. Additional Add-On PCBA Processes & Protection (unavailable as standalone services or processes)

Only as add-on services for our full turn-key PCB assembly processes, JosephSan offers additional protective and process enhancements to improve durability, reliability, and performance in harsh environments. These processes are only available as part of the PCBA module and help ensure long-term stability and robustness.

Key Additional Add-On PCBA Processes

(unavailable as standalone services or processes)

a. Conformal Coating – This coating protects PCBAs against moisture, dust, corrosion, and chemical exposure by applying a thin insulating layer over the assembled board.

b. Encapsulation & Potting – We offer potting solutions using epoxy, silicone, or urethane resins to shield sensitive components from vibration, shock, and contaminants for extreme environmental protection.

c. Selective Soldering for Through-Hole Components – This method is Ideal for mixed-technology PCBAs, ensuring high-precision soldering of through-hole components without affecting adjacent SMT components.

d. Ultrasonic & Chemical Cleaning – Removes flux residues, dust, and contaminants, preventing electrical failures and leakage currents, especially in high-reliability applications.

e. Depanelization & Routing – We provide precise depanelization using V-cut scoring, laser cutting, or routing techniques for panelized PCBs, ensuring clean, damage-free separation.

f. Press-Fit Assembly – An alternative to soldering, ideal for connector applications requiring high mechanical strength and durability.

JosephSan ensures that every PCBA meets customer-specific requirements by offering a range of value-added processes as add-on services to enhance product durability, performance, and long-term reliability.

INDUSTRIES WE SERVE

JosephSan provides PCBA solutions for a wide range of industries including:

Consumer Electronics

LED Lighting, Switch Mode Power Supplies, Communications

Industrial Electronics

IoT devices, Power Electronics, and Automation Systems

Automotive

ECU Boards, Vehicle Sensor Modules, LED Lighting Systems

Medical Devices

Healthcare Monitoring Systems, Diagnostic Equipment

Mission-Critical Industries

High-reliability PCB Assemblies for Vital Applications

Get A Quote For Your PCB Needs!

Looking for a trusted PCBA partner?

JosephSan is committed to delivering high-quality PCB assemblies and fast turnaround times.

Let's bring your electronic innovations to life! 🚀

Contact us at sales.team@josephsan.com.sg or submit the form below.

-%20ORIGINAL%20%5BDashboard%20Logo%20-%20510x510%5D.png)